The new Rotatrim Digitech+ DT1850 is an 2A0 Trimmer that cuts up to 20 sheets of paper or 2mm of materials, perfect for all types of digital printing requirements. As more and more applications are being printed on digital printers, the need for speedy and accurate trimming of the finished product has never been more important. The Digitech+ range has been designed to meet this demand and is based around the hugely successful and highly regarded, Technical T Series machine. The Digitech+ products are all metal construction, coupled with the high quality Sheffield Steel blades ensures excellent accuracy, reliability and robustness perfect for all types of printing requirements

Extreme accuracy is achieved by Steel Rotary and Flat Blades engineered in Sheffield with the materials used ensuring consistent accuracy on every single blade, all of which contribute to achieving as close to perfection as is possible, every time you use your Rotatrim. The 1½” brushed aluminium guide rail, ensures that the cutting head and therefore the rotary blade, is always perpendicular to the counter (flat) blade and that the precise cutting point, which is essential to ensuring the perfect cut is made, each and every time.

Both the cutting head and end frames of the DigiTechPlus DT Series are cast from aluminium and then painted, to offer an attractive finish. The all metal construction of these highly important parts, ensures that the machine is not only extremely robust, it also works in tandem with the large section square guide rail to add to the overall rigidity of the machine thereby completely eliminating head swivel during the cutting process. The elimination of cutting head swivel offers unrivalled levels of cut accuracy, both in terms of straightness and with virtually zero feathering of the work.

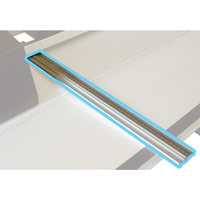

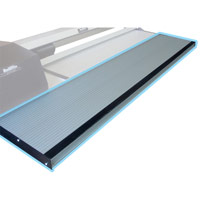

The heavy duty self-clamping clamp strip mechanism is made from an extruded aluminium to offer the highest possible level of accuracy and robustness, which is then mated to an extruded clear plastic clamp-strip. A rubber grip is included on the underside of clamp mechanism, to both protect the work form marking and to allow the machine, to grip very thin materials such as tissue paper. The clamping mechanism is self lifting allowing for easy placement of work and is then automatically and securely clamped once the cut commences. This allows for very large materials (up to 2.5M cut length) to be located and then accurately cut by a single user.