Laminating Types Explained

If you've never bought a laminator before then you may not be aware that there are many different ways laminating. You can choose between hot and cold lamination as well as using pouches or roll film. This page will explain each option clearly to help you make a more informed decision.

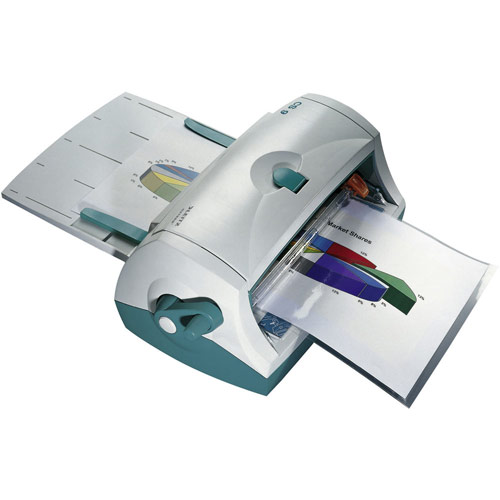

Hot Pouch Laminators are the most popular type of laminator used to encapsulate a document within a pouch which has 2 connected sides in which the item to be laminated is positioned. The pouch is coated with a heat-activated film, which melts when passed through the heated rollers and is then bonded under pressure, removing all of the bubbles and creating a tight seal.

View our full range of Hot Pouch Laminating Machines here

Cold Pouch Lamination are the best option when laminating heat-sensitive documents, which would include faxes, photos, and documents printed with an ink jet printer. Cold lamination can be safer and provide better UV protection than hot lamination. Cold laminating pouches use an adhesive that is activated with pressure, are easy and safe to use because they do not get hot and may not use electricity.

View our full range of Cold Pouch Laminating Machines here

Single Hot Roll Feed Laminators encapsulate a heat activated thermal film being applied on one side of the print. The finished result is trimmed to leave a clear border around the edge of the print, therefore encapsulated. Film is available in gloss and matt finishes in a range of thickness from 42 - 250 micron.

View our full range of Single Hot Roll Feed Laminating Machines here

Double Hot Roll Feed Laminators encapsulate a heat activated thermal film being applied to both sides of the print. The finished result is trimmed to leave a clear border around the edge of the print, therefore encapsulated. Film is available in gloss and matt finishes in a range of thickness from 42 - 250 micron.

View our full range of Double Hot Roll Feed Laminating Machines here

Cold Basic Roll Feed variable speed laminators are heavy-duty cold laminator systems perfect for delivering premium quality results for graphics and signage materials which are specifically supplied to sign makers, graphic designers, print shops, and vinyl/tape applicators. They use 2 cold, large diameter rollers for even pressure and a release liner take-up roller. Various laminating widths are available from 650mm to 1600mm

View our full range of Cold Basic Roll Feed Laminating Machines here